Beverage / Dairy / Nutrition / Food

Your Everyday Products Handled Every Day

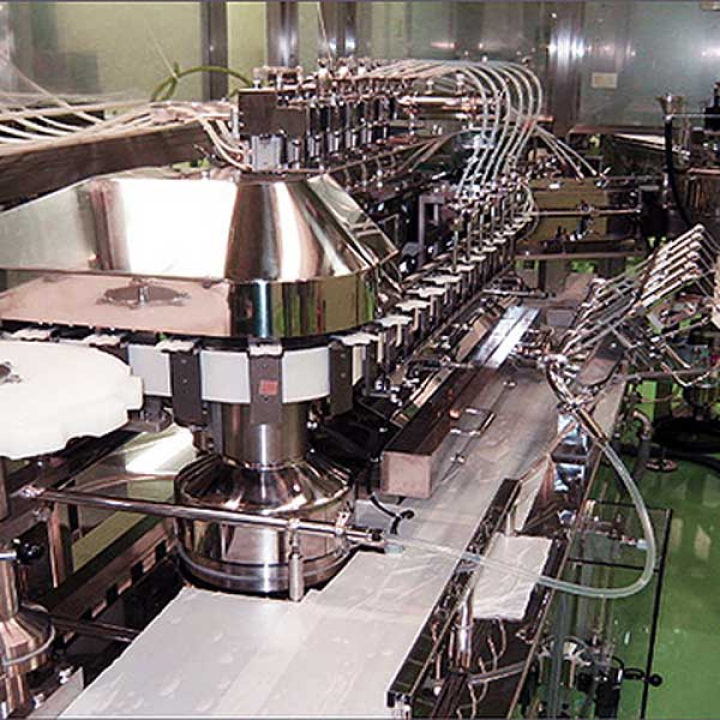

Major household, personal care and industrial manufacturers have depended on us to handle their products at varying rates. We’ve filled, fed, oriented, sorted, pucked, de-pucked, capped, labeled and assembled lip balm, deodorant, oil filters, and so much more in these industries. Our standard and customized systems handle products the world can’t live without. That’s why we’re the industry leading automation manufacturer for global conglomerates to contract packagers.

Contact

Have a question or need additional information?

Careers

Explore our current job openings.