Shibuya Products

Welcome to Shibuya

We strive to provide unmatched technology, quality, innovation, and customer service for your automated requirements. Our engineers excel in inspiration and innovation, continuously refining our design methodologies and expanding our product range to cater to your distinct requirements. Our goal is to minimize downtime, enhance overall equipment effectiveness, reduce total cost of ownership, and optimize efficiency.

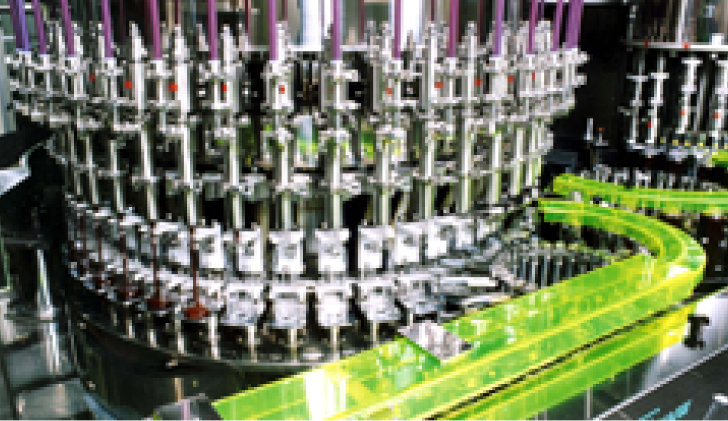

Filling & Capping Systems

Consumers want to be able to hydrate themselves anytime, anywhere. They have become more health-conscious, wanting more natural ingredients in their beverages, and more ecologically minded in reference to their environment.

Assembly & Placement Systems

We work with you to determine which assembly method best meets your project’s requirements. Our goal is to maximize machine efficiency while minimizing manufacturing costs!

Shibuya Product

Aseptic Filling Decontamination Systems

Aseptic filling provides robust product quality, minimal thermal impact on the beverage, and greater bottle design flexibility with maximum PET pottle light-weighting.

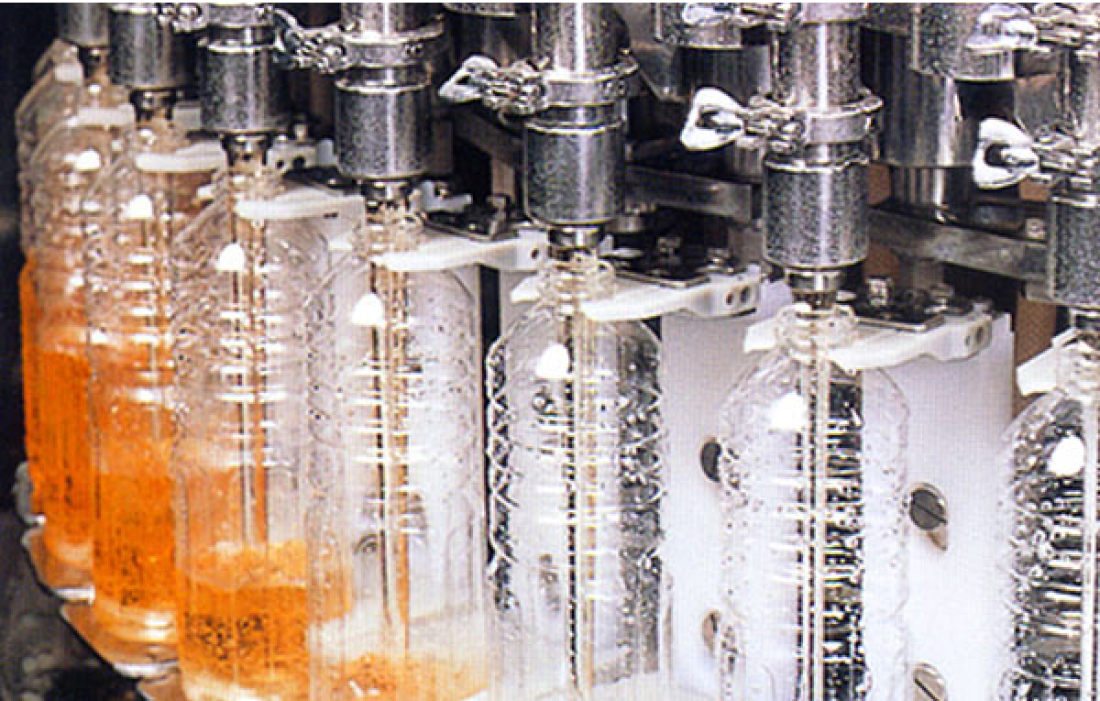

Bottling Systems

Systems for filling various containers such as bottles, cans, and PET bottles with a wide range of beverages and liquid products.

Packaging Systems

ystems for boxing or packaging a multitude of products including snacks, prepared foods, bottles, and everyday products.

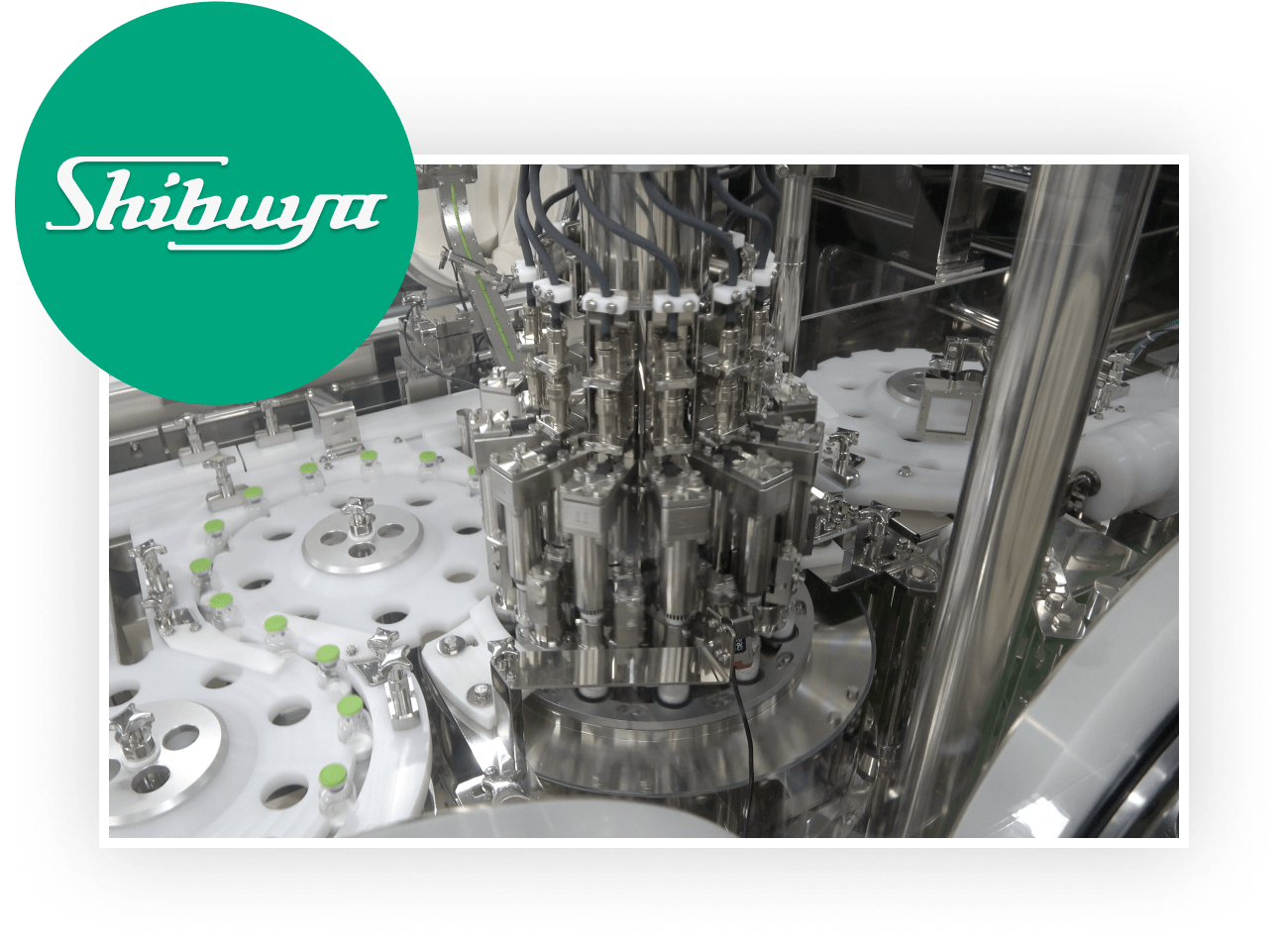

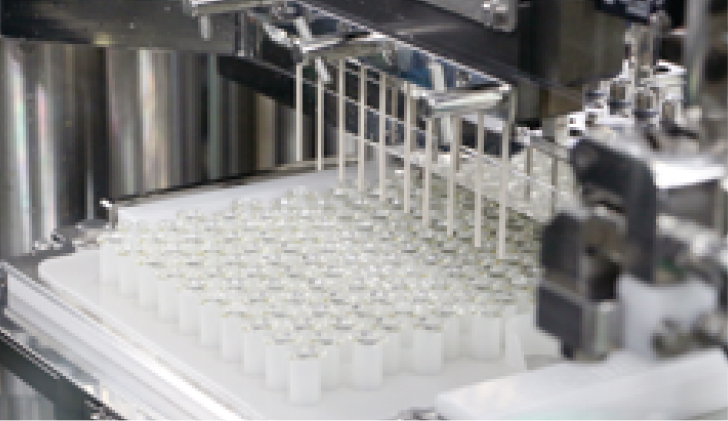

Pharmaceutical Manufacturing Systems

Systems and isolators for filling and packaging injection solutions, solid medication such as tablets and capsules, and various transfusion solutions for IV bags.

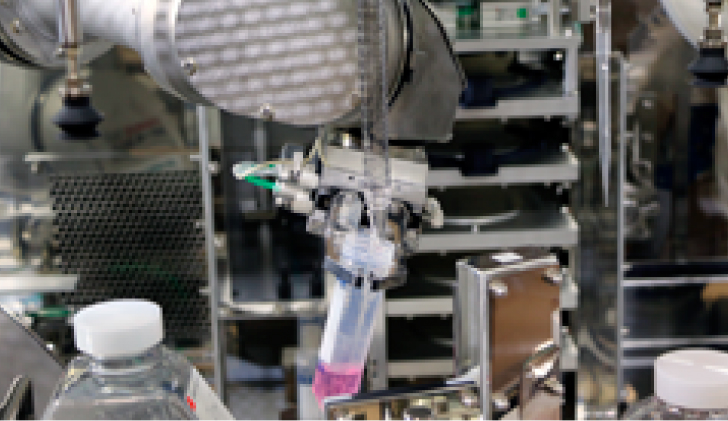

Regenerative Medicine Manufacturing Systems

Systems for cell culture and cell control that optimally respond to the needs of regenerative medicines laboratories such as those engaging in cell culture.

Shibuya Product Videos

Bottle Sterilizer by H202

Introduction to the EB System

Cap Sorter

Aligning Conveyor

CSD & Still Flexible Filler

Shibuya Product Line & International Sales

Contact

Have a question or need additional information?