Unscrambling & Feeding Systems

Why not choose the best: The Original Hoppmann Centrifugal Feeder System.

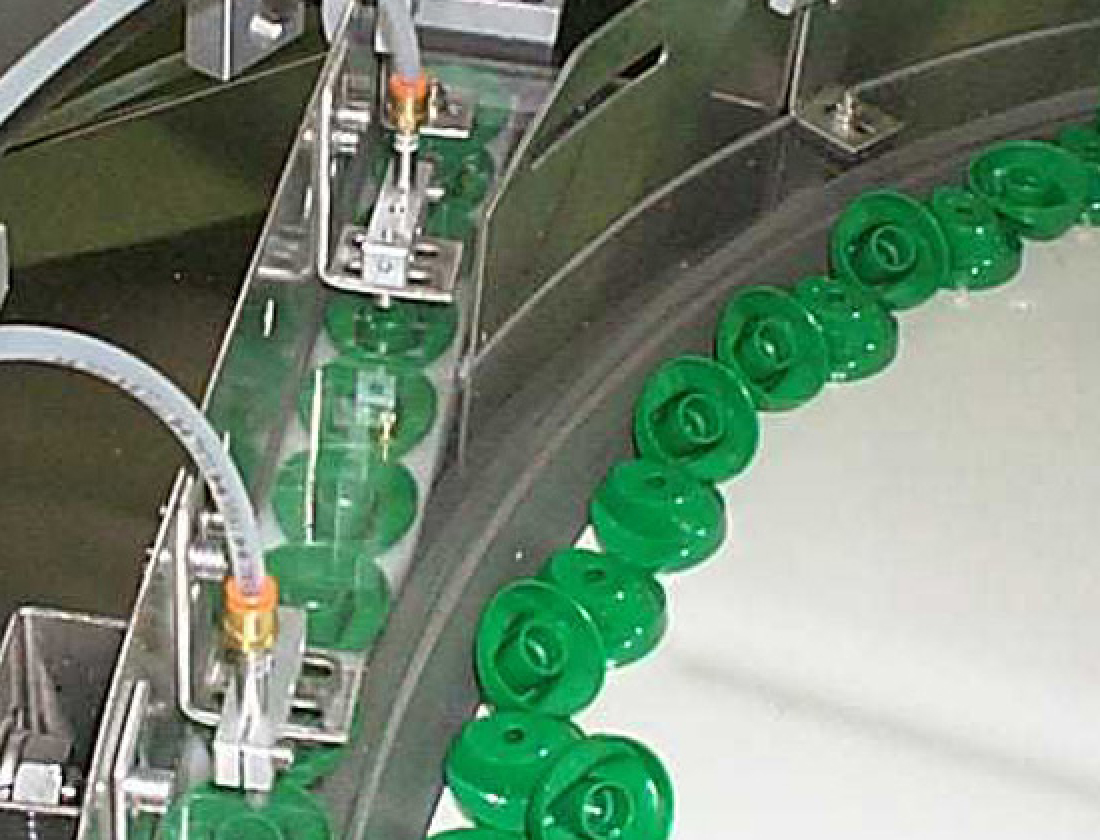

Centrifugal Feeders may be called many things – unscramblers, rotary bowls, parts sorters, feeder bowls, parts orientors, sorting bowls, feeders – whatever you want to call them, Shibuya Hoppmann’s Centrifugal Feeders get the job done. We have over 60 years experience building, designing, tooling, and optimizing our unscramblers to build creative solutions for all your parts handling needs. We have created an entire series of centrifugal feeders utilizing imaginative innovation, years of experience and leading technologies to meet your needs.

Shibuya Hoppmann’s Centrifugal Feeder is designed to run effortlessly to meet the lowest, to highest, parts per minute rate demands. We’ve listened to our customers and made a promise to them that our feeders and machinery are versatile, durable and reliable – easy to maintain, easy to operate and easy to run multiple parts! Try out our high speed – low drag solutions to your packaging needs.

- Beverage – Distillery Bottle Unscrambling System

- Nutritional/Dairy – Dairy Cap Sorter System

- Food – Frozen Sausage Feed System

- Household – Sponge Feed System

- Personal Care – Lip Balm Unscrambler

- Industrial – Caulking Tube Feed System

- Pharmaceutical – Wrapped Syringe Feed System

- Healthcare – Contact Lens Case Feed System

Our Product Catalog

- Caps

- Wrapped Noodle Packages

- Distillery Bottles

- Frosting Tubes

- Condiment Lids

- Candy Bars

- Bakery Nozzles

- Scoops

- Frozen Pancakes

- Tea Bags

- Yogurt Cups

- Filled Bottles

- Frozen Hamburgers

- Gum Packets

- Wrapped Chubs

- Dog Bones

- Coffee Containers

- Granola Bars

- Frozen Biscuits

- Manicotti Shells

See Our Products in Action

Watch our collection of YouTube Videos

Contact

Have a question or need additional information?

Careers

Explore our current job openings.

- Project Manager - Indianapolis, IN

- Experienced Electrical Technician - Madison Heights, VA

- Experienced Field Service Technician - Ohio

- Experienced Mechanical Technician (Day Shift) - Madison Heights, VA

- Entry Level Mechanical Technician (Day Shift) - Madison Heights, VA

- Bilingual (Japanese/English) Service Technician - Northern Virginia