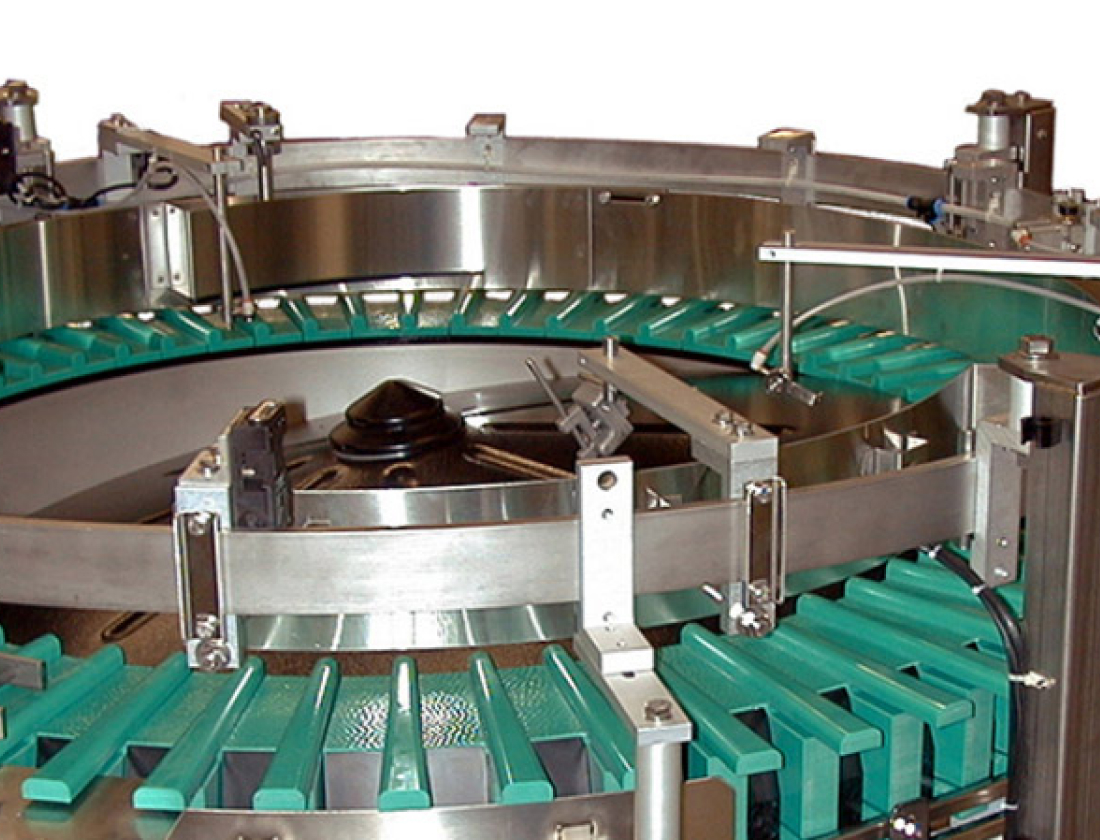

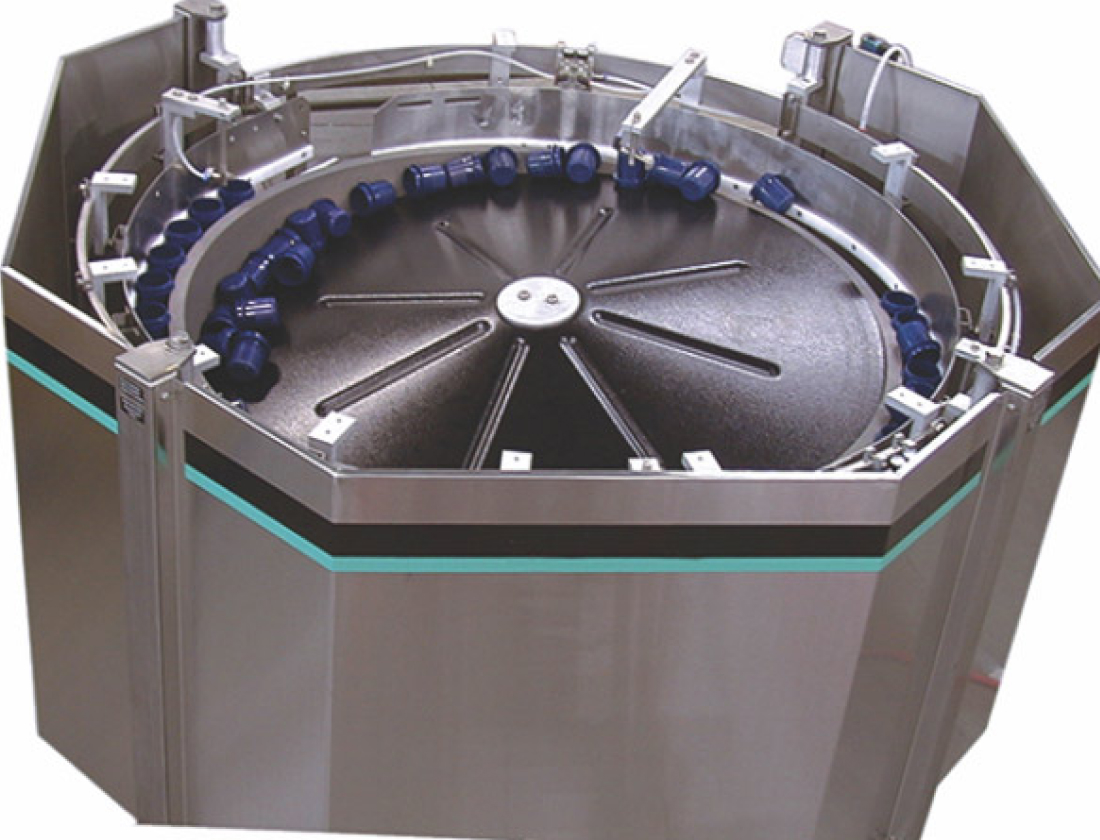

Hoppmann Centrifugal Feeders

The Original Centrifugal Bowl Feeder

A Hoppmann Centrifugal Feeder is designed to run effortlessly to meet the lowest, to highest, parts per minute rate demands. These centrifugal bowl feeders and unscramblers are the most versatile – using simple, yet consistent designs, rugged durability, flexible technology, and our years of experience.

Shibuya Hoppmann offers different styles of orienters and unscramblers for different requirements. The FT-Series efficiently handles small, medium and large parts at high speeds; the FS-Series incorporates a unique urethane scallop rim design to orient/singulate bottles, vials, tubes, barrels, and other cylindrical shapes; the FRS-Series uses interior elevators to gently lift large or bulky parts onto a scalloped rim for easy orientation, and the FT-15-AC is autoclavable and designed for small, fragile and precise parts that need to be unscrambled or oriented in a sterile, pharmaceutical environment.

Choose dependability and build a lasting relationship with the Original centrifugal bowl feeder Manufacturer: Hoppmann.

Our Product Catalog

- Caps

- Wrapped Noodle Packages

- Distillery Bottles

- Frosting Tubes

- Condiment Lids

- Candy Bars

- Bakery Nozzles

- Scoops

- Frozen Pancakes

- Tea Bags

- Yogurt Cups

- Filled Bottles

- Frozen Hamburgers

- Gum Packets

- Wrapped Chubs

- Dog Bones

- Coffee Containers

- Granola Bars

- Frozen Biscuits

- Manicotti Shells

See Our Products in Action

Watch our collection of YouTube Videos

Contact

Have a question or need additional information?

Careers

Explore our current job openings.

- Project Manager - Indianapolis, IN

- Experienced Electrical Technician - Madison Heights, VA

- Experienced Field Service Technician - Ohio

- Experienced Mechanical Technician (Day Shift) - Madison Heights, VA

- Entry Level Mechanical Technician (Day Shift) - Madison Heights, VA

- Bilingual (Japanese/English) Service Technician - Northern Virginia